Unimil’s Industrial Park is located in Piracicaba, SP, and is equipped with advanced resources, specialized labor, and cutting-edge technology. We meet automaker specifications and supply parts to the aftermarket, with improvements, innovations, and exclusive specifications.

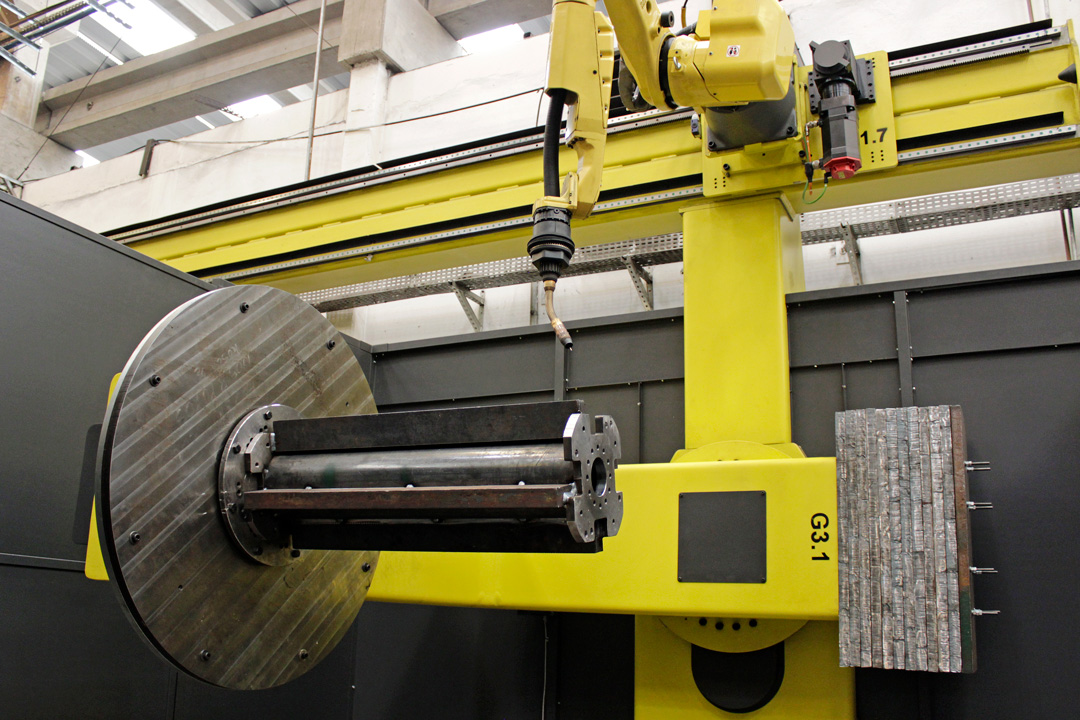

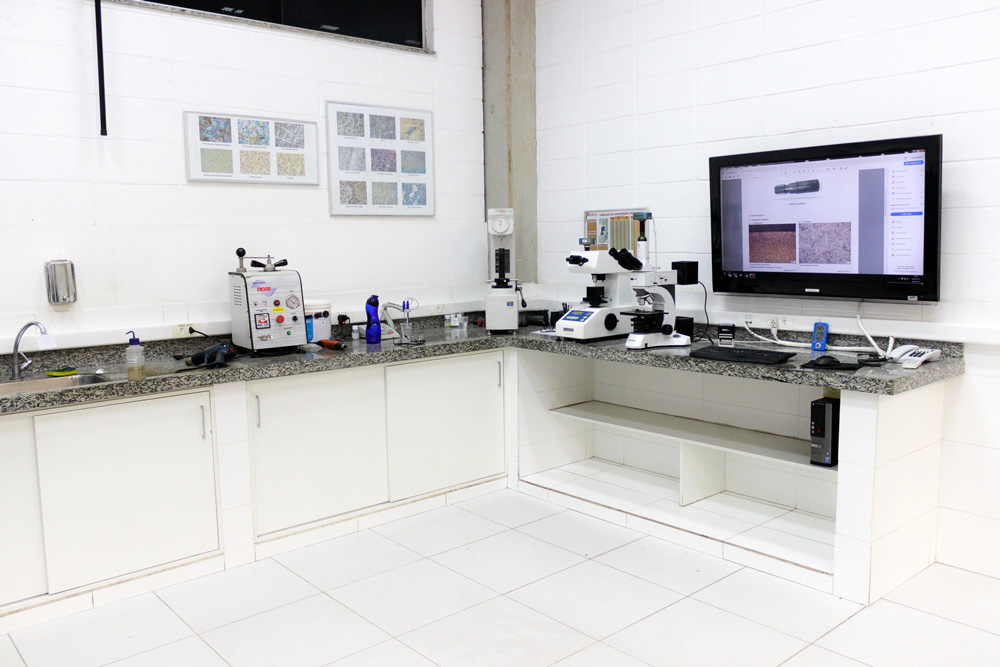

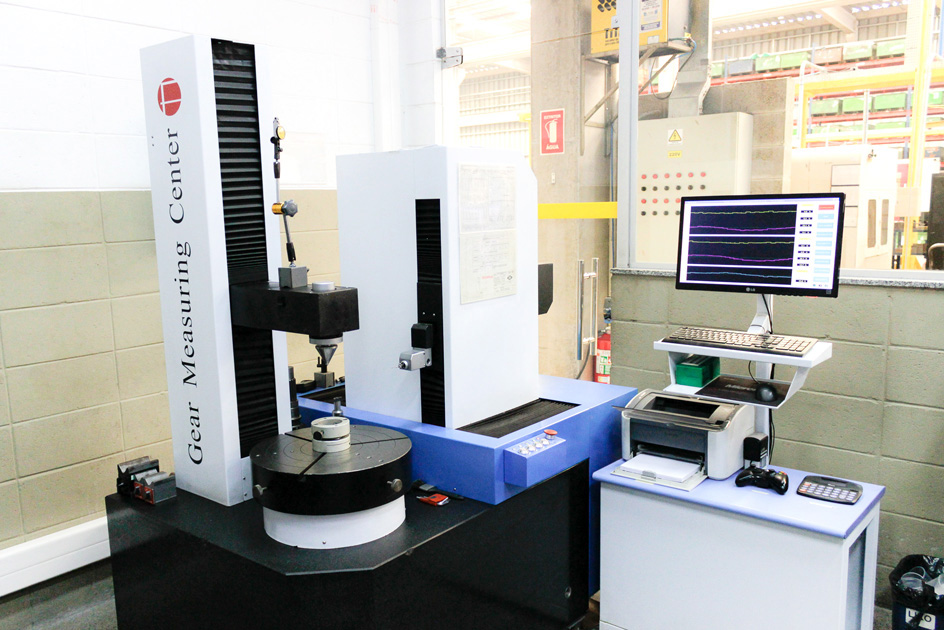

Unimil specializes in the production of structural parts, components, machined parts, transmission, and hydraulic cylinders. Our factory has boilermaking, machining, a robotic center, laser cutting, forming, electrostatic painting, and metallographic and dimensional laboratories. With ISO 9001 certification throughout the management system, we guarantee the quality of replacement parts for John Deere and Case sugarcane harvesters. Our commitment to quality control is supported by a broad control structure and analyses carried out from raw material to finished product, through our laboratories.

In addition, we have an integrated logistics system that allows us to have strategically located branches in the country’s main sugar-energy centers to quickly serve all customers. We also export our parts to more than 20 countries.

At Unimil, we are committed to providing reliable and efficient solutions, aiming to reduce the cost per ton harvested and increase the availability of your cane harvester.